Development of packaging design

Our company has installed and successfully operates the whole complex of modern technological equipment which is necessary for the complete cycle of production of various types of packaging. Any type of package begins with the design. Experienced professionals of design studio, together with print technologists, prepare the original layouts before the print and send them for the further print output.

We use the newest software that allows us to provide the color correction according to the hardware profile, and adaptation to the process of flexographic or gravure printing. The choice of print method depends on the print edition, customer requirements, design, etc. Flexographic printing allows grouping the designs with the same geometry in a draw at random, but with a comparable price of the finished package flexographic printing is different from the gravure printing. Gravure printing has excellent, almost photo-realistic quality of the printed image, which can be seen in a smooth transition from one color to another. In addition, halftone dots are not visible to the naked eye.

In addition, gravure printing enables precise exposure of Pantone colors without the slightest change color throughout of circulation, even a large one, what is important, for example, to save the brand color of the company. (In the slang of technology, this parameter is called the circulation stability.) At the same time, all these advantages are inextricably connected with high costs and long periods of the prepress, since gravure printing, unlike flexographic printing, used the metal shafts as the plates.

Extrusion

Product line of extruders that produces a polythene film with the desired properties for each customer is a guarantee of high quality products. We produce polythene film from LDPE, EVA, LLDPE, mLLDPE films and mixtures of MDPE, HDPE, coPP, with thickness from 20 to 200 microns and a width of 2200 mm.

Forward and reverse printing up to 8 colors

Modern equipment for flexographic and gravure printing, experienced printers, print-proven technology, strong locking and phase control of process parameters for each order, all that can provide the high quality of print throughout the printing process with linearity up to 100 lpsm and width up to 1200 mm.

Lamination

The use of multiple technologies of lamination (solvent or without solvent lamination) allows us to create a packaging material with different properties based on the selection of appropriate combinations of materials. Due to this, we are among the three main Ukrainian producers of packaging for ketchup, tomato paste and alcoholic beverages products.

Stock layout

During the stock layout, we provide precision cutting of rolls with the required diameter, high quality of the ends and uniform winding width of the roll. Depending on the customer wishes, as well as the conditions of transport, we package the rolls of finished products in stretch film and prepare pallets with accompanying labels.

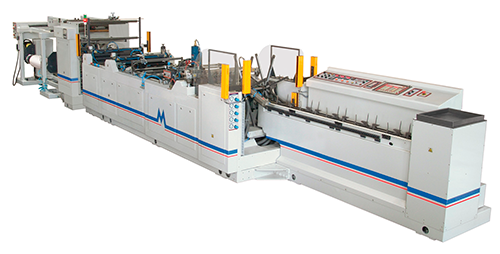

Production of the packets

We can manufacture all types of ready-made bags from the film, at the request of our customers. Product line of packers allows producing three-seam packets, stand-up pouch, packages with zip-lock, with a notch for easy opening, etc. In the production of bread packets (with any type of bottom, perforation and valves), we are the absolute leaders, and deliver products throughout Ukraine and Russia.

Conclusion

We have the extensive experience in the production of packaging for various industries. We constantly study and experiment with different polymer materials and help customers to get the optimal combination of material for packaging. We offer not only the safety and excellent package appearance, but also the optimum price of our products. This gives us the opportunity to offer you the unique price/quality ratio and obtain the whole range of packaging from the same manufacturer, regardless of the printing method, the material structure and circulation.

As a result, you get the benefits of speed, transportation costs and working capital savings (our clients receive trade credit) and all this with the highest quality products. The company operates a system of certification and implementation of measures and standards in the production process according to ISO 9001.

If you order the sample of material with the desired structure, you can see the quality of our products and assure yourself of our unique price/quality ratio’s offer. Working with us, you will sidestep rivals very fast and for long time.