KHASK LTD – Ukrainian producer of packaging materials, uses in the production cycle extrusion machine to arrange extrusion lamination. The process of extrusion lamination is almost identical for all types of basis, which makes it possible to work with a wide spectrum of film forming raw materials and various types of basis. As an example, there are materials we produce: PET + PE, BOPP + PE, paper + PE, cardboard + PE and so on. Extrusion lamination is practically identical for all types of base, that allows to work with a wide range of film-forming raw materials and various types of base.

Extrusion lamination is manufacture technology for special packaging, which is coating of film substance on the basis type (substrate) chosen. In the manufacture process solid polymer is placed into a special machine – extruder, where it is heated to the melting temperature and poured on the basis. In this respect, extrusion lamination allows to create complex composite materials with increased robustness and water resistance.

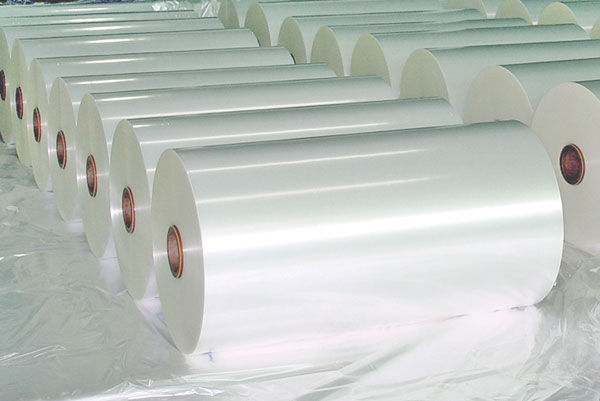

Finished product is reeled.

Also, modern extruder allows us to create composites of two basses, sealing them together with melting polymer. Second unwinding unit makes it possible to produce multilayer materials by gluing different substrates with polymer: paper + PE + paper, paper + PE + foil, cardboard + PE + foil, PE + paper + PE, etc.

Cut edge of finished product is cut with a pneumatic device and edges, appearing in the process of coating is cut with razor blades.

Adding various additives to the process of extrusion lamination we can change the properties of the polymer coating.

Extrusion lamination, parameters:

|

Parameter: |

min |

max |

|

Finished product width |

700 mm |

1300 mm |

|

Polymer coating thickness |

8 µm |

30 µm |

|

Original roll weight |

|

≤1200 kg |

|

Applied image width |

|

≤1000 kg |

|

Cutting width of finished rolls |

50 mm |

1300 mm |