Stretch is packaging material made of plastic film. It is used everywhere for packaging of goods, cargo, boxes, food products and other things. Stretch film has become so widespread in the packaging sphere due to its main property - absence of adhesive layer, which allows you to protect packaging from adhesive residues on the surface or from damages when removing the packaging film. Sealing process is due to the material layers overlapping.

Stretch film from KHASK LTD

Our company is one of the leaders on the domestic market for stretch sales. However, in addition to sales, we are also engaged in the manufacture of this packaging material.

Feature of the stretch we manufacture is a high ability to reversibly stretch. This parameter means that the film can be stretched without risk of damage. Company KHASK LTD manufactures a stretch with an index of reversible stretching (elongation) up to 300%.

Also our stretch passes high-level tests for punctures and tears.

Application

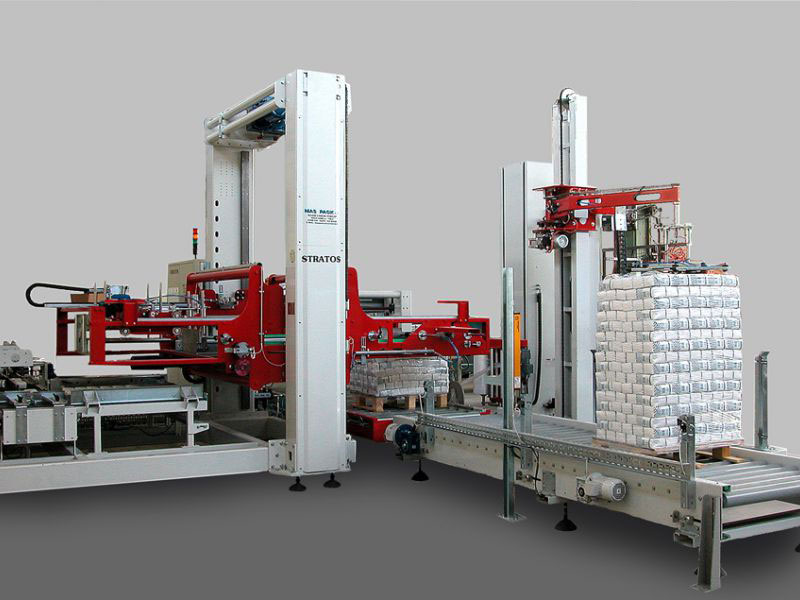

The most common way to apply stretch is to fasten a large quantity of small-sized transported cargo to one monolithic block. For example, all products manufactured by our company are packed in corrugated cardboard boxes and installed on a pallet. However, during transportation the boxes can be damaged, contaminated or even scattered from the pallets, so before sending the entire pallet is wrapped with a dense stretch of a few layers on a special installation.

Such a packaging will allow you not only to transport the cargo easier, but also to protect it from spoiling, environmental influences during storage and also significantly to simplify the process of its loading / unloading.

Advantages:

-

High index of the tightening force (it will be possible to pull the loads installed on pallets tightly);

-

High resistance to ruptures and punctures of the material, which will serve as additional protection against damage and contamination;

-

Manual stretch film does not require special packaging devices;

-

Operates under a wide temperature range;

-

Pre-stretching allows stretching the film before use, which reduces the amount of consumable material.

Characteristics

Stretch film from Ukrainian producer - KHASK LTD is of different thickness. We offer a wide choice starting from 15 to 30 µm. standard thickness is 17, 20 and 23 µm.

Basically, stretch film is divided into 2 types: pallet and food. The second is used for food packaging, where the film does not contact the product. This type of stretch does not contain substances that can harm human body. The first type (pallet stretch) is divided into 2 more types:

- For manual rolling (packaging is carried out manually)

-

For machine rolling (Pallets are packed on special machines - palletizers)

Manual stretch (also called manual stretch film)

Main application field of this stretch is food manufacture, but it can also be used for individual packaging of any product, as well as cargo packaging, where the intensity of packaging does not exceed 5 pallets per hour and there is no pallet wrapper.

This type of stretch film, delivered by company KHASK LTD in rolls of small size with weight from 1,5 to 3 kg including plug (gross weight). Standard thickness for such type is 17 and 20 µm and width - 500 mm. Guaranteed ability to pre-stretching is 75-150%. Rolls are packaged in corrugated cardboard boxes of 6 pieces. In the process of products or raw materials packaging with hand stretch film, special dispensers (devices that help to conveniently fix the roll and adjust the tension of layers) are often used when wrapping the goods.

Characteristics:

|

Толщина, мм |

Ширина рулона, мм |

Количество погонных метров в рулоне |

Вес рулона, кг |

Гарантированное предварительное растяжение, % |

|

17 |

500 |

180 |

1,7 |

150 |

|

17 |

500 |

220 |

2,0 |

150 |

|

17 |

500 |

230 |

2,1 |

150 |

|

17 |

500 |

270 |

2,4 |

150 |

|

20 |

500 |

175 |

1,9 |

150 |

|

20 |

500 |

200 |

2,1 |

150 |

|

20 |

500 |

230 |

2,4 |

150 |

|

23 |

500 |

210 |

2,5 |

150 |

*Company KHASK LTD can manufacture a roll by individual parameters for each customer.

Machine stretch (pallet stretch)

Type of stretch, which is most often used by large industries, where groups of cargo or single gross units need to be pulled together before being transported. In most cases, this type of film is used to fasten large consignments of goods on a pallet before transporting them or placing them in a warehouse for storage.

The most common items for packaging in such stretch are boxes, PET and glass containers in the primary packaging (drinks in shrink film), building blocks, bags and so on.

The difference of machine stretch from manual stretch is concluded in the name. For its rolling onto a product or group of products automated machines that have a pre-tension regulator are used.

Standard parameters: film width – 500 mm, thickness – 20 and 23 µm, gross weight (including plug) – 15,1 kg.

Machine stretch, manufactured by KHASK Company divided into several types:

- Regular and Standard – designed for use on semi-automatic pallet packaging machines of low productivity. Prestretch does not exceed 200%

- Power – applied on the same machines as Regular and Standard. Preliminary stretching index is up to250%

-

Super (Superpower) – used on equipment with a high level of productivity and speed of packaging. Prestretch – up to 330%.

Machine stretch, specifications:

|

Толщина, мм |

Ширина рулона, мм |

Количество погонных метров в рулоне |

Вес рулона, кг |

Гарантированное предварительное растяжение, % |

|

20 |

500 |

1500 |

15,1 |

до 200 |

|

23 |

500 |

1300 |

15,1 |

до 200 |

* Company KHASK LTD is able to produce rolls with individual parameters for each customer.

Prestretch of the stretch film

Characteristics of the material, which is worth attention to be paid, because it is one of the main indicators of the quality of packaging film. Along with prestretch, there are values such as the strength of the material and the rate of recovery of the form. According to the parameters you can calculate how many square meters of stretch you will need for quality packaging of your products - the higher they are, the less stretch is consumed.

Along with the growth of prestretch index of the stretch film, the price indicator for this packing material is also growing. However, it is necessary to note that buying a better stretch, you save on the cost of material on packaging.

Food packaging stretch (PE)

Other common name is cling-stretch. The main feature of this category is that it can be used in the food industry, because its materials do not contain substances that harm human body. In addition, food packaging stretch is solid, resistant to punctures and tears, as well as has a better reversible stretching.

Food stretch is used everywhere in fast food chains, supermarkets, households, etc.

Standard thickness is 5 – 11 mm.

Basic characteristics of food stretch films:

|

Толщина, мм |

Ширина рулона, мм |

Количество погонных метров в рулоне |

Вес рулона, кг |

Гарантированное предварительное растяжение, % |

|

8 - 10 |

300 - 450 |

300 - 1500 |

3,5 - 7,8 |

175 |

|

9 cutter box (металл. нож) |

300 |

300 |

3,5 |

175 |

Main advantages of food stretch:

-

Protective function when densely contacting with products or raw materials.

-

Increasing of saleable condition.

-

Packaging does not require special devices.

-

Cheaper and more convenient in use than wrapping paper.

-

Low price per square meter, that allows you to compete with many types of polymer films (not only in the field of food packaging).

-

Ecological compatibility in comparison with conventional PVC stretch film